Over 451 quotes processed

CNC Prototypes in 3 Days. No Minimums. Quotes in 12–48 Hours.

Request a quote in just 30 seconds. Got questions? We've got answers.

From NASA widgets to beer-can helicopters, we’ve seen it all.

No job’s too weird for us.

Certified Inspection & Compliance Standards

✅ Geometric Dimensioning & Tolerancing (GD&T):

Full GD&T capability, including flatness, concentricity, and more

Functional gaging with custom fixtures to verify complex callouts

Per-print compliance to ensure every part meets exact specs

✅ Trusted for Precision & Compliance:

10+ years of experience machining tight-tolerance parts for aerospace and energy sectors

ITAR registered (authorized to handle defense-related components)

Skilled with ISO 9001 and AS9102 inspection processes.

Every part is measured, documented, and verified. No assumptions. No shortcuts.

We GUARANTEE speed, precision and qualiTY

Single-part quotes returned within 12 hours; quote packages within 48 hours.

3-day prototype turnaround available after material sourcing.

No minimum order quantities required. One-off prototypes and scalable repeat production available.

Standard tolerances of ±0.003” with availability to hold down to ±0.0002” depending on material and geometry

All parts are reviewed and approved by the owner/operator for quality assurance.

Materials We Specialize In

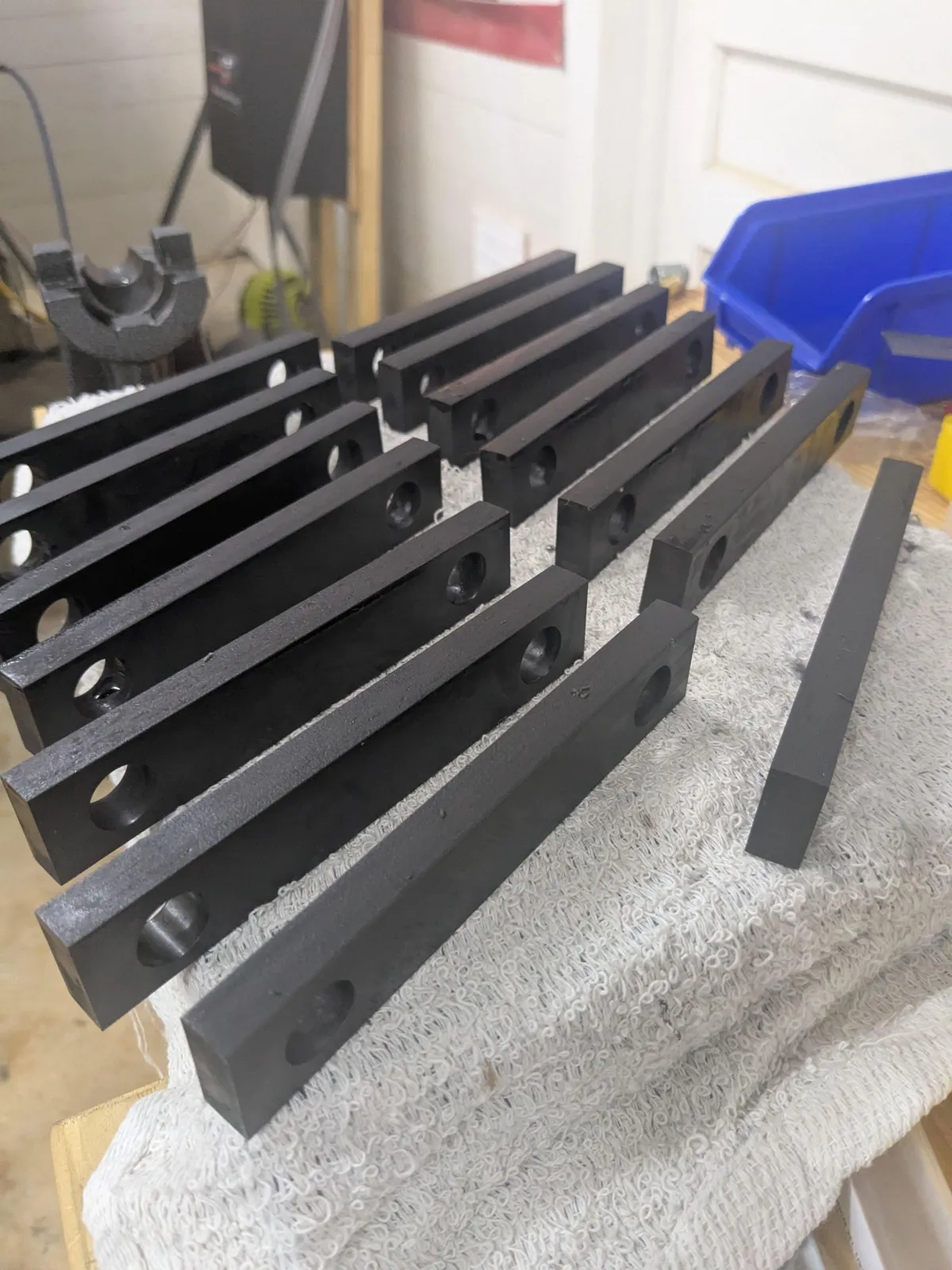

Alloy & Tool Steels

Grades: 4140, 4340 (pre-hardened), A2, D2 (annealed), O1, S7

Applications: Ideal for molds, dies, and high-wear components

Capability: Extensive experience machining pre-hardened and annealed tool steels with tight tolerance control.

Titanium Alloys

Grades: Commercially Pure, 6Al-4V (Grade 5), 6Al-4V ELI

Applications: Aerospace, medical, and high-performance structural parts

Capability: Skilled in managing titanium's challenges including heat, rigidity, and surface integrity.

Stainless Steels

Grades: 17-4PH, 316L, 304

Applications: Corrosion-resistant and biocompatible parts

Capability: Experience across industries including medical, food-grade, and aerospace.

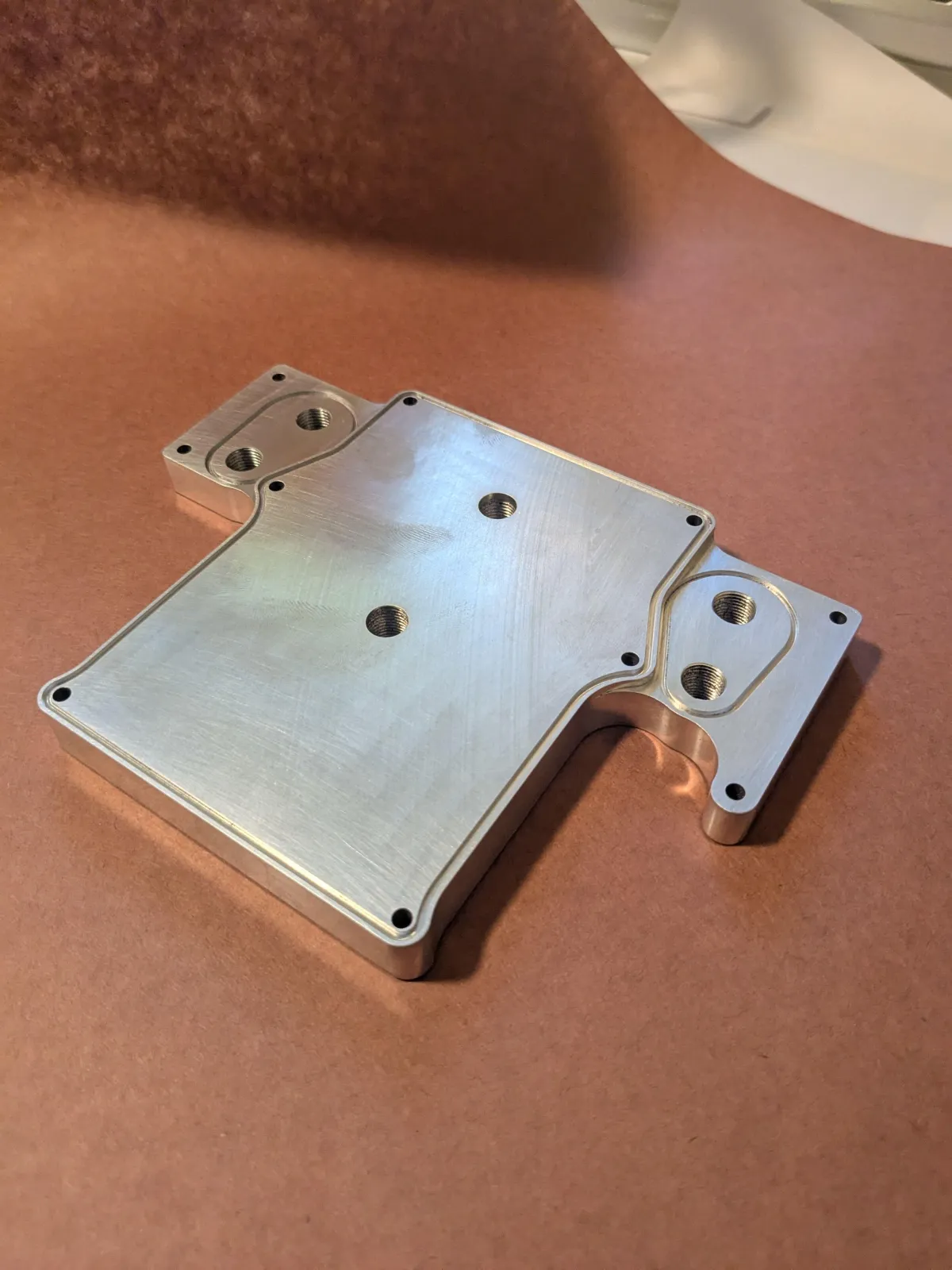

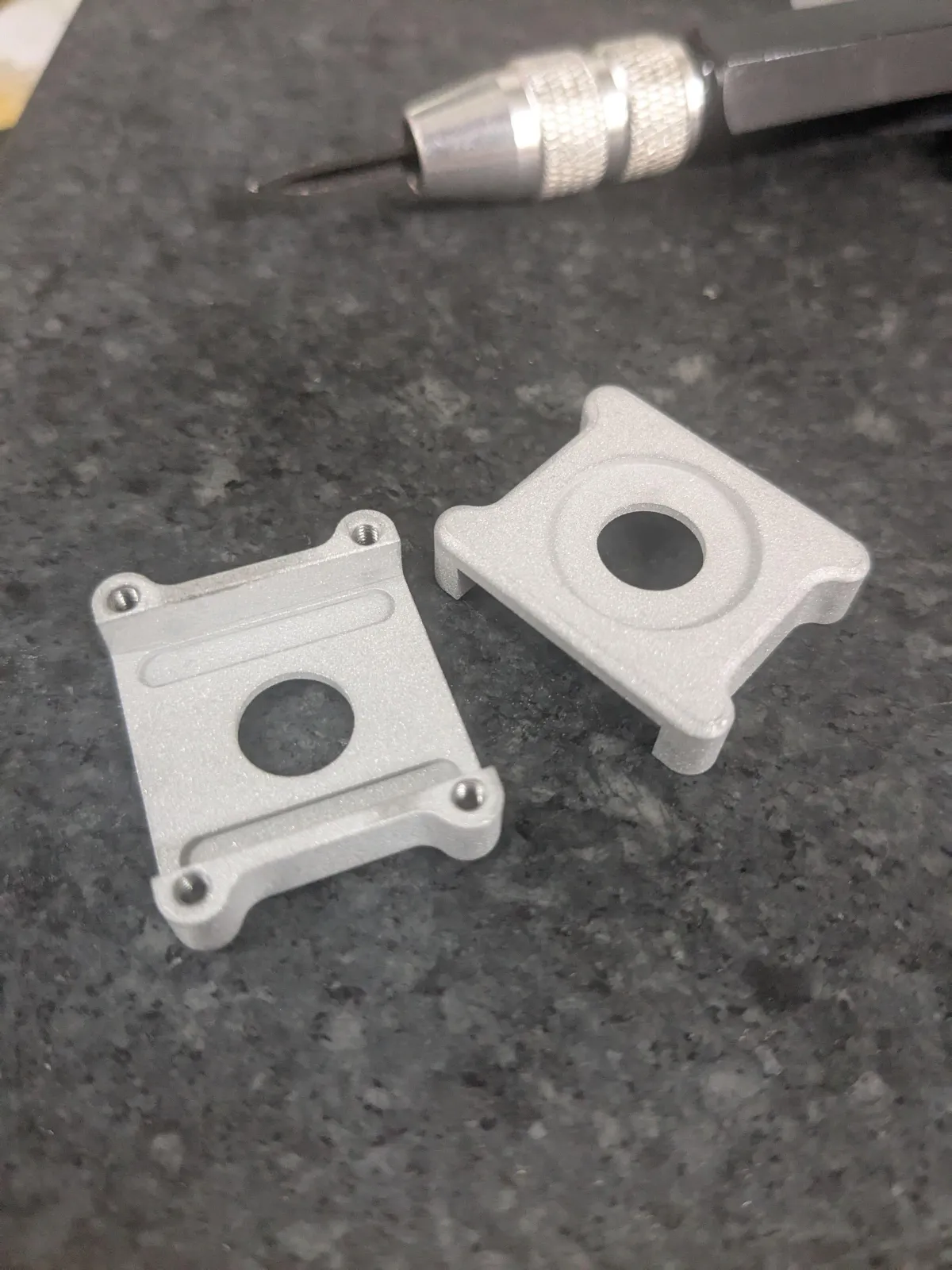

Aerospace Aluminum

Grades: 7075-T6, 6061, 2024

Applications: Lightweight structural components

Capability: High-speed machining with excellent surface finish on aerospace-grade alloys.

Engineering Plastics

Materials: PEEK, Ultem, Delrin, Torlon

Applications: High-performance, chemical-resistant, and insulative components

Capability: Precision machining with minimal thermal deformation and clean edge finishes.

Prickly Pear Prototypes is a CNC machine shop based in Luling, Texas, specializing in tight-tolerance prototypes and small-to-medium batch runs using high-performance and exotic materials. Since 2021, we’ve supported industries like medical and energy with fast, cost-effective solutions and a strong focus on precision, communication, and reliability. Many of our projects are protected by NDAs, and we take customer privacy, intellectual property, and confidentiality seriously. From one-off parts to production-ready components, we treat every job with the same level of care and quality our clients rely on.

Frequently Asked Questions

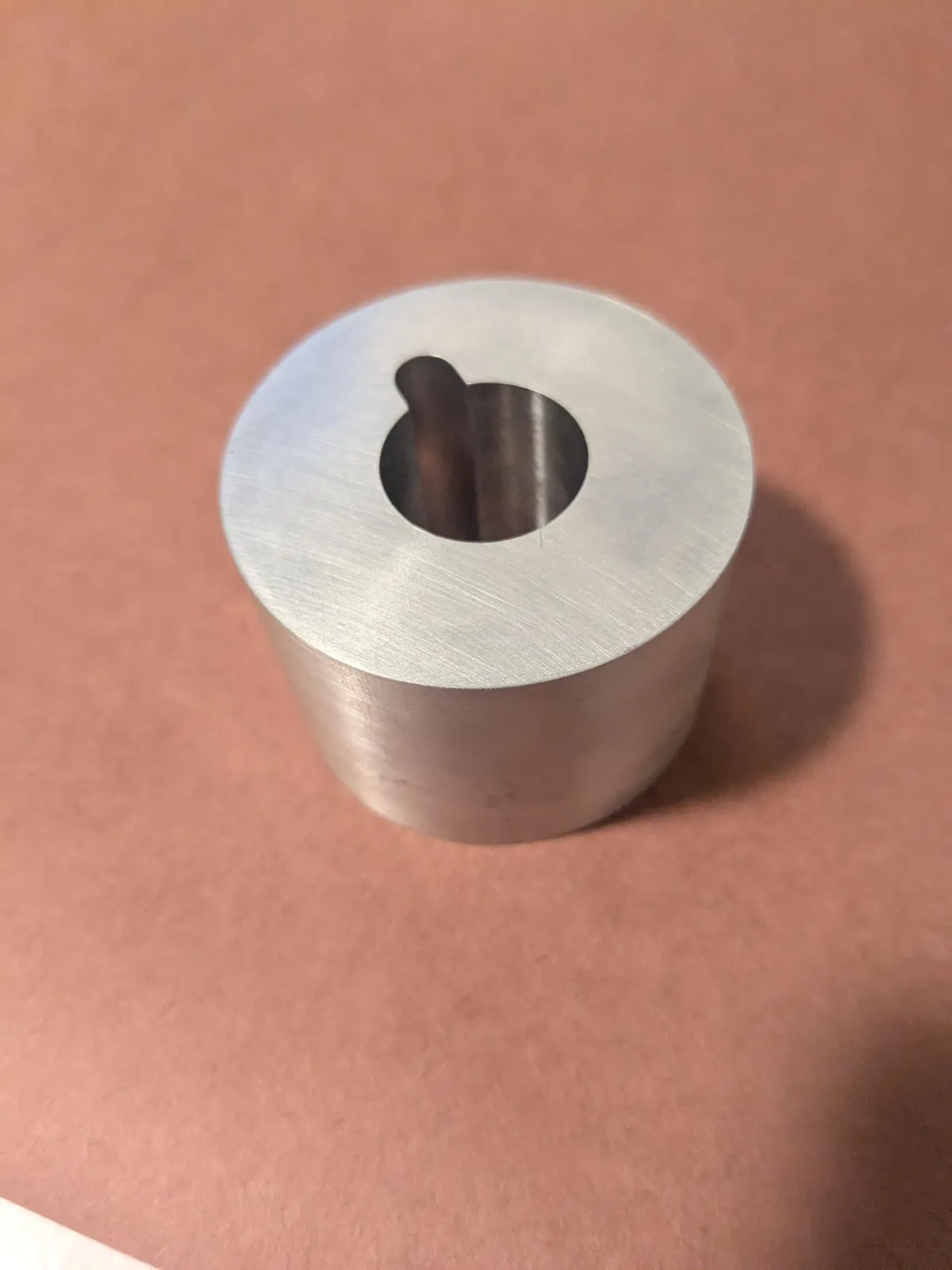

What CNC machines do you use?

Our primary machining center is a Fanuc Robodrill, known for its speed, reliability, and precision. It features a 10,000 RPM spindle, 30-tool automatic tool changer, and travels of 20" x 16" x 20". This machine is ideal for high-mix prototype work, machining exotic materials, and jobs that demand fast cycle times.

We also utilize a manual lathe for straightforward turning operations, FDM 3D printing for prototyping non-metal components (up to 280°C), and a full metrology suite to ensure dimensional accuracy and quality control. Every machine in our shop is in active use and optimized for daily production.

What tolerances can you hold?

We hold tolerances down to ±0.0005" depending on part geometry and material. All parts are validated against client prints with full documentation and traceability.

What industries does Prickly Pear Prototypes serve?

We serve clients across medical devices, energy, semiconductors, aerospace, advanced communications, and R&D. We specialize in tight-tolerance, functional prototypes and low-to-mid volume production.

What materials do you work with?

We machine a wide range of materials including:

- Alloy & tool steels (4140, 4340, A2, D2, O1, S7)

- Titanium alloys (CP, Grade 5, Grade 5 ELI)

- Stainless steels (17-4PH, 316L, 304)

- Aerospace-grade aluminum (7075-T6, 6061, 2024)

- Engineering plastics (PEEK, Ultem, Delrin, Torlon)

What are your quoting and turnaround times?

Single-part quotes: typically within 12 hours

Quote packages: within 48 hours

Prototype turnaround: as fast as 3 days after material sourcing

We also support rush jobs when feasible

Is there a minimum order quantity (MOQ)?

No. We do not require any minimum order quantities. We support one-off prototypes, small batches, and scalable repeat production.

Do you sign NDAs or protect intellectual property?

Yes. We routinely work under non-disclosure agreements and take client confidentiality very seriously. All files, prints, and communications are treated as proprietary and secure.

Are you ITAR registered and compliant?

Yes. Prickly Pear Prototypes is ITAR registered and fully compliant with U.S. export regulations. We follow strict protocols to ensure all technical data and defense-related work remains secure and in full accordance with the International Traffic in Arms Regulations (ITAR). Clients can trust us to handle sensitive projects with the highest level of confidentiality and control.

Who will be overseeing my project?

All projects are personally reviewed and approved by Ben Simon, the shop’s owner and lead machinist, to ensure quality, accuracy, and on-time delivery.

What kinds of parts have you made?

Examples include:

- 7075 aluminum safety cams

- 316 stainless semiconductor sealing plates

- Teflon wire holders for medical devices

- Delrin and nylon brackets

- Alloy steel automotive stiffening braces

- Titanium test fixtures and one-off designs

and much, much more.

Testimonials

Luke S.

"Please send invoice. Super happy with this part."

Confidential Client

“Responsive, fast, and accurate. Exactly what we needed to move forward with our prototype. Thanks Ben!”

Jordan R.

“Got everything done quicker than expected. Parts came out clean and exactly how we needed them."

Lets chat!

Location: Luling, Texas

Instagram

Mail

LinkedIn